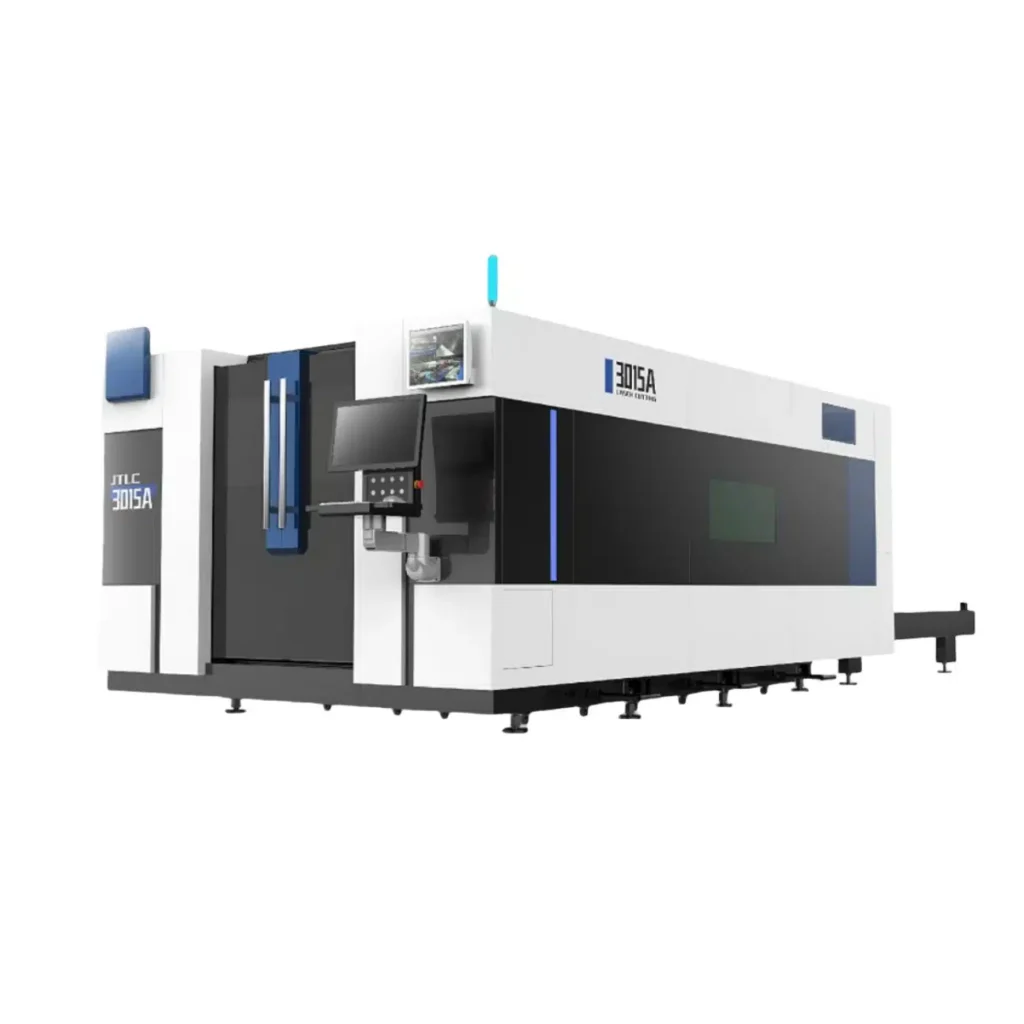

In the modern metal fabrication industry, LaserChina stands as a trusted metal laser cutter manufacturer known for precision, reliability, and advanced engineering. Metal laser cutting technology has revolutionized the way industries design and shape metal components offering exceptional accuracy, speed, and flexibility compared to traditional cutting methods.

What Is a Metal Laser Cutter?

A metal laser cutter uses a high-powered laser beam to cut, engrave, or shape metals like stainless steel, aluminum, brass, copper, and carbon steel. The laser melts or vaporizes the material along a defined path, producing a clean and precise cut. This process is computer-controlled, ensuring minimal human error and consistent output.

Key Specifications of LaserChina Metal Laser Cutters

1. Laser Power Options

LaserChina offers a wide range of power levels from 500W to 20,000W allowing users to select the ideal setup based on the type and thickness of metal.

-

Low power (500W–2000W): Suitable for thin sheets and intricate designs.

-

Medium power (3000W–6000W): Ideal for medium-thickness metals.

-

High power (10,000W+): Designed for industrial-scale cutting with heavy-duty materials.

2. Cutting Bed Size

Available in various sizes to accommodate small components or large metal sheets, ensuring flexibility for different production needs.

3. Laser Source

Equipped with advanced fiber laser sources, ensuring consistent beam quality, low maintenance, and energy efficiency.

4. Precision and Accuracy

Cutting tolerance typically within ±0.02 mm, ensuring excellent edge finish and repeatability.

Characteristics That Define LaserChina Machines

1. Durable Frame Design

Each unit is built with a rigid steel structure to reduce vibration and maintain cutting precision even during high-speed operations.

2. User-Friendly Control System

LaserChina integrates intuitive software interfaces compatible with CAD/CAM programs, simplifying design-to-cut processes.

3. Energy Efficiency

Fiber laser systems consume significantly less energy than CO₂ lasers, reducing operational costs while maintaining high output.

4. Automatic Focusing System

Smart focusing technology adjusts automatically to metal thickness, improving accuracy and efficiency.

5. Advanced Cooling and Safety Features

Built-in cooling systems and safety interlocks ensure continuous and safe operation, even in demanding environments.

Advantages of Choosing LaserChina Metal Laser Cutters

-

High Precision: Perfect for detailed metal patterns and parts.

-

Faster Production: Laser cutting is faster than plasma or mechanical methods.

-

Minimal Waste: Narrow kerf width minimizes material loss.

-

Low Maintenance: Fewer moving parts and durable components reduce downtime.

-

Versatile Applications: Ideal for automotive, aerospace, machinery, and custom fabrication industries.

-

Cost-Effective: Long lifespan and reduced energy consumption lower overall costs.

Buying Guide: How to Choose the Right Metal Laser Cutter

1. Determine Your Material Type and Thickness

Select a power level suitable for the metals you work with most frequently. For thicker metals, consider a higher-wattage model.

2. Assess Production Volume

For large-scale operations, choose a model with a larger cutting bed and automation features to boost productivity.

3. Evaluate Software Compatibility

Ensure the laser cutter supports your preferred design software for smooth workflow integration.

4. Check After-Sales Support

LaserChina provides training, technical assistance, and spare parts—helping you maintain consistent production quality.

5. Consider Budget and ROI

While higher-powered models require more investment, they often deliver better long-term returns due to faster cutting speed and lower energy use.

Why Choose LaserChina?

LaserChina has earned its position as a top metal laser cutter manufacturer through continuous innovation, quality assurance, and a customer-first approach. Every machine is tested for performance, durability, and precision before delivery, ensuring clients receive unmatched reliability and cutting accuracy.

Whether you are a small workshop or a large manufacturing facility, LaserChina provides customized solutions designed to improve efficiency, cut quality, and operational safety all backed by strong technical support and long-term service.

In summary: LaserChina’s advanced metal laser cutting systems combine cutting-edge technology with durable engineering, making them the ideal choice for industries seeking precision, performance, and productivity in every cut.