Embroidery has been a timeless form of craftsmanship, but the secret to modern, precise stitching lies in embroidery digitizing. This process converts creative artwork into a language embroidery machines understand, ensuring every stitch follows a planned path for consistency, accuracy, and beauty.

From small monograms to detailed corporate logos, embroidery digitizing makes professional stitching possible on garments, hats, patches, and promotional items. It’s where technology meets artistry, transforming digital images into beautifully embroidered realities.

What Exactly Is Embroidery Digitizing?

Embroidery digitizing is the process of turning an image or logo into a digital stitch file using specialized software. This file directs the embroidery machine on how to sew each part of the design — where to start, stop, change colors, and what stitch type to use.

A good digitizer analyzes artwork, understands the fabric, and plans the stitching sequence carefully. Unlike simple printing, embroidery involves physical threads, so stitch tension, density, and direction all matter to achieve professional results.

How the Embroidery Digitizing Process Works

The digitizing process is both technical and artistic. Here’s a step-by-step overview of how it happens:

1. Artwork Cleanup and Preparation

The image is cleaned, simplified, and converted into clear outlines suitable for stitching. Complex images may be reduced to solid colors or vector lines.

2. Importing into Digitizing Software

Software like Wilcom, Hatch, or Embrilliance is used to trace the artwork and assign stitches to each section. Each color, shape, and border gets its own stitch plan.

3. Choosing Stitch Types

Depending on the design, the digitizer uses:

-

Satin stitches for text and borders

-

Fill stitches for large areas

-

Run stitches for outlines and fine details

4. Adding Underlay and Adjustments

Underlay stitches form a stable base to prevent puckering. The digitizer also adjusts stitch density to match fabric type and design size.

5. Test Stitch and Refinement

A test run reveals issues like spacing or thread tension. Adjustments are made until the design stitches perfectly, ready for bulk production.

Why Embroidery Digitizing Is So Important

Digitizing is the foundation of every successful embroidery project. Even high-end machines rely on well-crafted files to produce accurate results.

-

Consistency: The same design can be replicated across hundreds of garments with exact precision.

-

Efficiency: Optimized stitch paths reduce thread breaks and machine stops.

-

Quality: Balanced density and underlays ensure professional finishes and longevity.

-

Scalability: Once digitized, designs can easily be resized or modified for different uses.

Without quality digitizing, embroidery can look uneven, distorted, or unprofessional—no matter how advanced the machine.

Essential Tools and Software for Embroidery Digitizing

Choosing the right software can make all the difference. Here are some of the most trusted programs in the industry:

-

Wilcom Embroidery Studio: A top-tier professional tool offering advanced control and stitch simulation.

-

Hatch Embroidery: Designed for small businesses and independent creators.

-

Embird: Flexible and affordable software for both beginners and pros.

-

Pulse DGML: Ideal for high-volume commercial embroidery operations.

-

Brother PE-Design: Great for home embroiderers looking to learn professional techniques.

Each tool allows users to visualize how a design will sew, preventing costly production errors.

Common Stitch Types Used in Digitizing

To achieve professional results, digitizers combine different stitch types:

-

Satin Stitch: Perfect for lettering and outlines, giving a shiny finish.

-

Fill Stitch: Best for large filled areas like backgrounds.

-

Run Stitch: Used for thin lines and small details.

-

Underlay Stitch: Strengthens the fabric base for stability.

-

3D Foam Stitch: Adds raised, textured effects often used in cap embroidery.

The right combination ensures balance between beauty, texture, and durability.

Real-World Example: Custom Logo Embroidery

Imagine digitizing a company logo for uniforms. The digitizer starts by separating color zones, applies satin stitches for the lettering, and uses fill stitches for the background shape. After testing, the file is ready for mass production—ensuring every employee uniform carries an identical, professional logo.

This precision and repeatability make embroidery digitizing indispensable for brand identity and corporate consistency.

Challenges in Embroidery Digitizing

Even skilled professionals face technical challenges that require experience and testing:

-

Fabric Stretch: Stretchy materials demand more underlay support.

-

Tiny Details: Small text often needs density and angle adjustment.

-

Color Layering: Gradients require careful stitch sequencing.

-

Thread Breaks: Overly tight paths or poor tension cause interruptions.

Expert digitizers anticipate these issues and adjust settings accordingly for smooth, uninterrupted embroidery.

Benefits of Professional Embroidery Digitizing

Working with professional digitizers brings clear advantages:

-

Flawless Results: Every stitch is engineered for perfection.

-

Time Efficiency: Optimized files run faster with fewer machine stops.

-

Design Flexibility: Easily scale designs without losing detail.

-

Fabric Compatibility: Adjustments ensure stability across materials like denim, fleece, or polyester.

-

Long-Term Value: Digitized files can be reused indefinitely for future projects.

These benefits make professional digitizing essential for embroidery businesses and hobbyists alike.

Industry Applications of Embroidery Digitizing

Digitizing impacts a wide range of industries:

-

Corporate Branding: Logos on uniforms and caps.

-

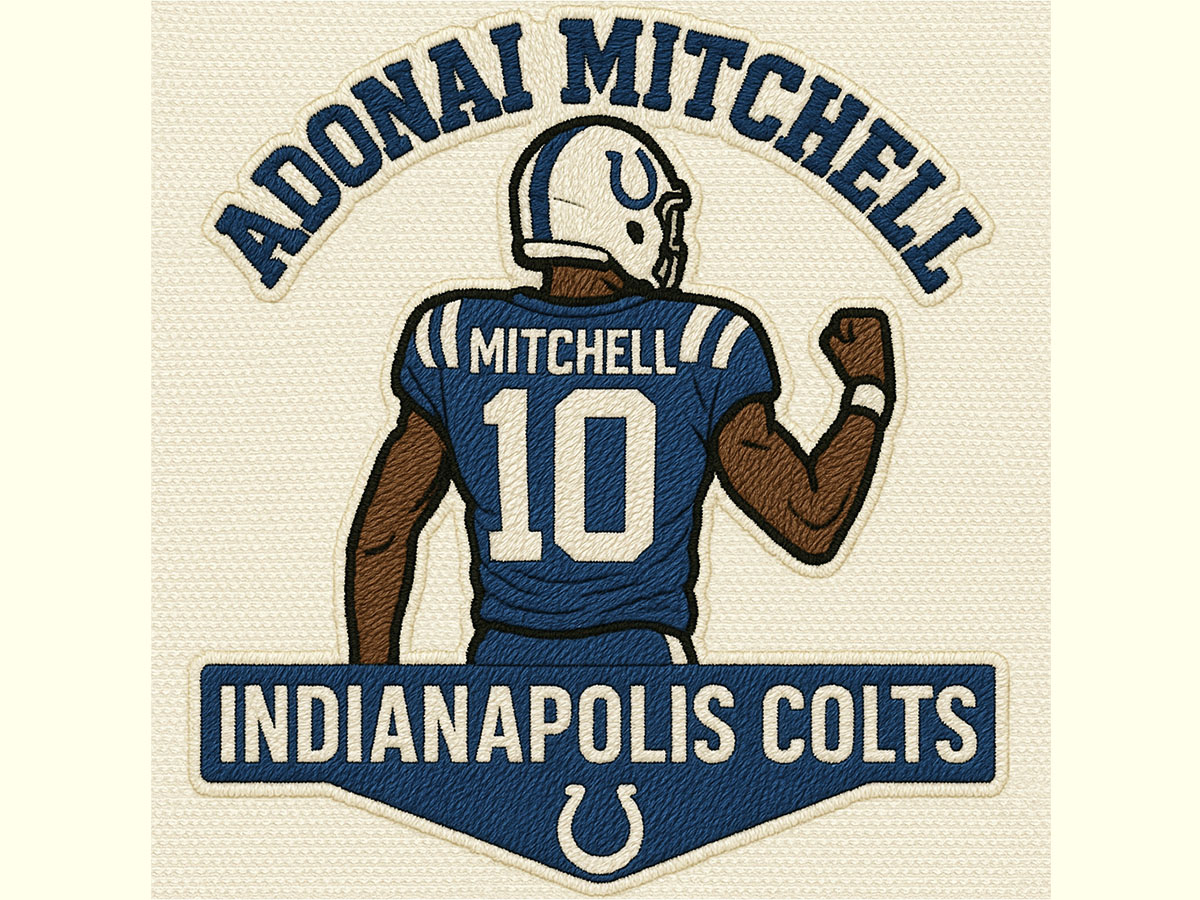

Sportswear: Team patches, names, and mascots.

-

Fashion: Designer embroidery on denim and jackets.

-

Custom Merchandise: Personalized gifts and promotional items.

-

Patch Production: For collectors, clubs, and organizations.

No matter the field, embroidery digitizing ensures visual consistency and professional presentation.

Best Practices for Embroidery Digitizing

To achieve top-quality results, follow these proven tips:

-

Always use high-resolution artwork or vector files.

-

Choose the right stitch density for the fabric.

-

Test your design on similar material before production.

-

Avoid overcrowding colors or excessive detail in small areas.

-

Keep lettering at least 0.25 inches tall for clarity.

Following these guidelines ensures your embroidery remains sharp and long-lasting.

Future of Embroidery Digitizing

The future is bright and tech-driven. AI-assisted digitizing tools are already helping designers automate pathing and color mapping. Cloud-based collaboration allows faster turnaround, while smart software predicts tension and density adjustments automatically.

As sustainability becomes a priority, digitizing also supports eco-friendly embroidery by reducing thread waste and optimizing production.

FAQs About Embroidery Digitizing

1. What is needed to start embroidery digitizing?

You’ll need quality software, a good understanding of stitch types, and basic design knowledge.

2. Can I digitize designs myself?

Yes, but achieving professional results requires practice and technical understanding of embroidery behavior.

3. How long does digitizing take?

Simple designs can take 1–2 hours, while complex logos may take several hours depending on detail.

4. Why is digitizing important for branding?

It ensures your logo looks consistent and professional across every garment, maintaining brand recognition.

5. What file format should I request?

Common formats include DST, PES, and EXP—depending on your machine’s brand.

Conclusion

Embroidery digitizing is the invisible craftsmanship behind every professional embroidered design. It merges creativity, technology, and precision—turning digital artwork into durable, stitched art that stands the test of time. Whether for business branding, fashion, or personal expression, the quality of digitizing defines the excellence of embroidery itself.

With skill, the right software, and a deep understanding of materials, embroidery digitizing continues to be the foundation of modern embroidery artistry—making every stitch a reflection of perfection.