ingAlso known as plummer block bearings, pillow block bearings are one of the most utilized bearing housings found in manufacturing and mechanical applications. They offer rigid support for shafts and rotating equipment while allowing for smooth operations, reduced friction and extended service life. Designed to be easy to install and replace, pillow block bearings can even be interchanged in the field if necessary. This makes pillow block bearings important in any industries that need heavy machinery, precision equipment, and continuous production.

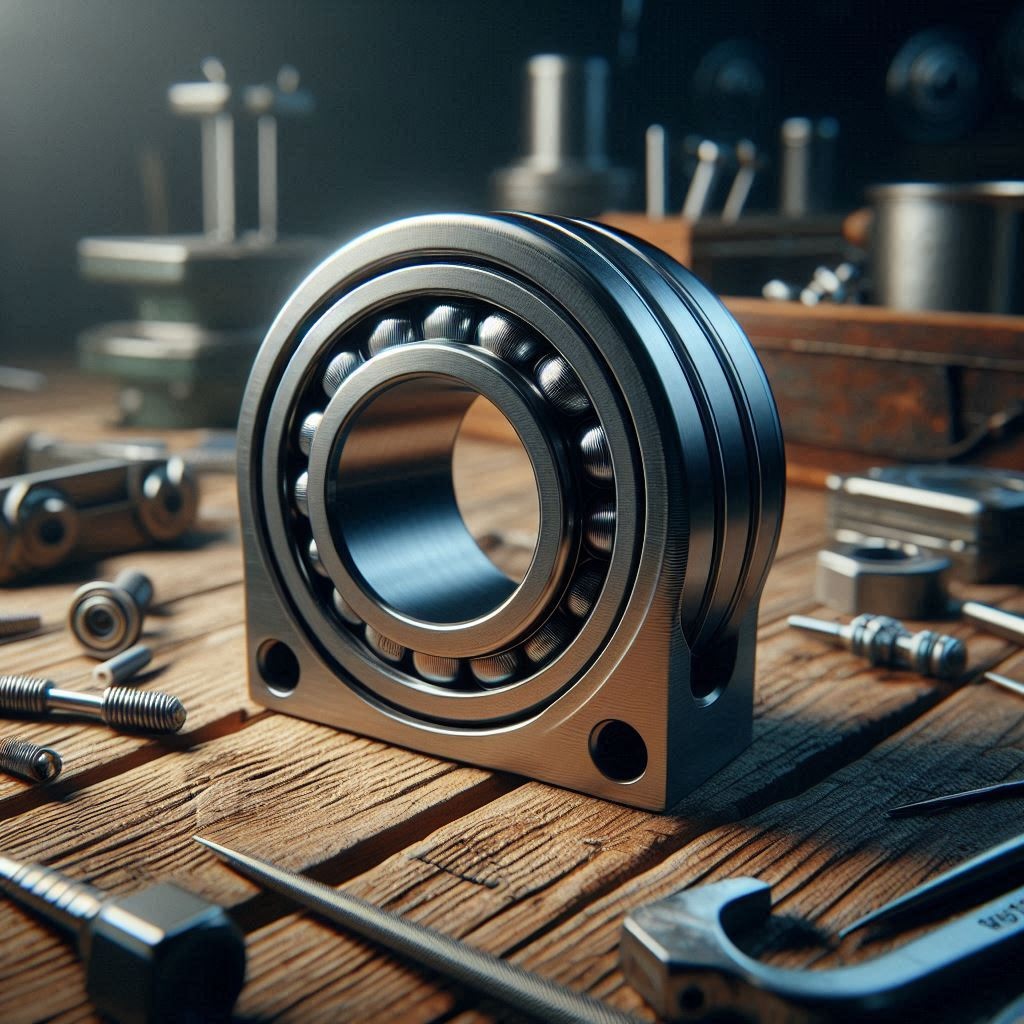

What is a Pillow Block Bearing?

A pillow block bearing is an engineered bearing that allows support of a rotating shaft employing the proper compatible bearing inserts. Pillow block bearings come in various housing materials such as cast iron, stainless steel, or thermoplastics. Pillow blocks can support relatively heavy loads and tolerate shock loads and vibration in demanding working conditions, which makes pillow block bearings very widely used throughout a variety of industries.

Key Features of Pillow Block Bearings

Indian pillow block bearings offer a balanced mix of efficiency, dependability, and value, which solidifies their choice across a wide variety of industries. Technicians can easily install and replace pillow block bearings, reducing downtime during disassembly and reassembly of equipment without requiring special tools. Manufacturers design these bearings to handle both continuous and shock loads, emphasizing reliability over long service periods in harsh working environments. They produce pillow block bearings in a wide variety of materials, sizes, and seal types to match the specific requirements of each application. For applications where noise matters, manufacturers engineer pillow block bearings with tighter tolerances to ensure low noise and minimal vibration.The low cost of pillow blocks, and the long service time and over time reduced current maintenance, equal a well-priced and sound decision.

Applications of Pillow Block Bearings

Pillow block bearings are the most adaptable machines that serve many different industries. Although, Pillow block bearings owe their wide use to their versatility, they have high strength, and ease of operation. In agriculture, they hold tractor implements, harvesters, and irrigation equipment in place to ensure reliable performance in tough field conditions. In manufacturing, they support textile machinery, conveyors, and packaging systems, enabling efficient and smooth operations.

Construction sectors have a strong impact on heavy-duty equipment such as asphalt or cement mixers, crushers, or lifting equipment. In the food and beverage industry, pillow block bearings, with hygienic stainless-steel housings, provide a high level of corrosion resistance and help make sure the security and safety of food processing operations. In automotive and railways, pillow block bearings help boost the effectiveness and longevity of gear boxes, drive systems, and axle shafts. Pillow block bearings are an indispensable part of our modern industrial processes.

Manufacturing Process of Pillow Block Bearings

The manufacture of pillow block bearings is a precision-centric process that combines engineering with polished quality standards. The manufacturing process begins with engineers selecting materials based on the application, typically using quality cast iron, stainless steel, or thermoplastic for housings. They cast or machine the housings to strict specifications, ensuring the strength and durability required for a long service life. Accordingly, manufacturers then produce the bearing inserts from hardened steel, including the rolling elements, inner races, and outer races, to withstand heavy loads. During the assembly and alignment process, technicians mount the inserts with seals and lubrication to enhance longevity and enable smoother operation. Finally, quality teams conduct stringent assessments on each bearing to confirm reliable performance under load and vibration across diverse applications.

Advantages of Pillow Block Bearings

Pillow block bearing is appreciated for their reliability and durability while needing little maintenance, which is attractive to industries looking for longevity and operational reliability. Besides this, Pillow blocks are preferred for their low maintenance, long life, and easy replacement, keeping operations efficient in light or heavy-duty uses.Pillow block bearings are also less expensive than other bearing options, giving you reliability, and durability at a reasonable cost.

Conclusion

Pillow block bearings serve vital purposes in providing efficient and dependable rotary machinery across numerous industries. They are durable, versatile, and easy to maintain, making them essential for industries worldwide. Its component that moves production, ensures performance, and minimizes downtime.