Flexible metal hoses are essential components in modern industries where durability, flexibility, and safety are top priorities. These hoses are designed to transport fluids, gases, and steam under pressure or vacuum conditions, while accommodating movement, vibration, and thermal expansion that rigid piping cannot handle. From power plants and refineries to HVAC systems and aerospace applications, flexible metal hoses play a crucial role in ensuring system efficiency and reliability.

What is a Flexible Metal Hose?

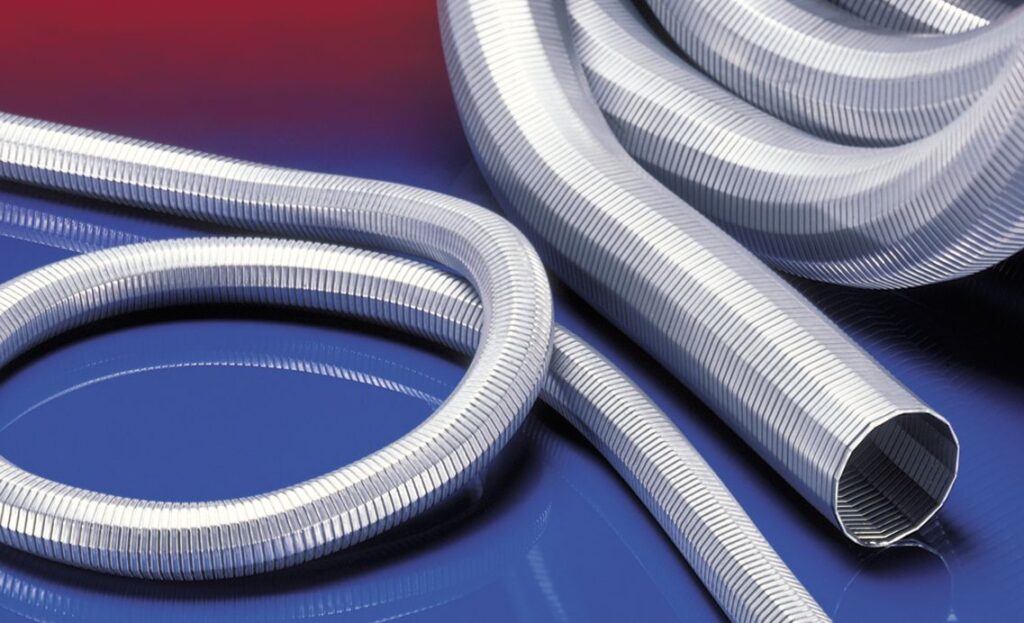

A flexible metal hose is a tubular component made from stainless steel or other corrosion-resistant metals. It typically consists of two main parts:

-

Corrugated Tube: The inner hose with spiral or annular corrugations that provide flexibility and pressure resistance.

-

Braid Layer: A wire mesh (usually stainless steel) wrapped around the hose to enhance pressure handling and prevent elongation during use.

This design allows the hose to bend, absorb vibration, and handle misalignment without compromising strength or leak-tight performance.

Key Features and Benefits

-

High Flexibility:

Flexible metal hoses can bend easily in multiple directions, making them ideal for systems with tight space constraints or frequent movement. -

Excellent Pressure Resistance:

The metal construction, combined with the external braid, allows the hose to handle high internal pressures safely. -

Temperature Tolerance:

Unlike rubber or plastic hoses, flexible metal hoses can withstand extreme temperatures — from cryogenic levels to several hundred degrees Celsius. -

Corrosion and Chemical Resistance:

Stainless steel construction provides strong resistance to corrosion, oxidation, and chemical exposure, ensuring long service life even in harsh environments. -

Vibration Absorption:

These hoses minimize vibration transfer between equipment, protecting sensitive components and reducing system fatigue. -

Leak-Free Performance:

The all-metal design ensures reliable sealing, making it suitable for high-purity, high-pressure, and hazardous applications.

Common Applications

-

Oil & Gas Industry: Used for fuel transfer, steam lines, and compressor connections.

-

Chemical Processing: Ideal for transporting reactive or corrosive chemicals safely.

-

Power Generation: Absorbs thermal expansion and vibration in boiler and turbine systems.

-

HVAC Systems: Connects pumps, chillers, and air-handling units with vibration isolation.

-

Automotive & Aerospace: Carries exhaust gases, hydraulic fluids, or coolant in high-performance systems.

-

Food & Pharmaceutical Industries: Stainless steel hoses ensure hygienic transfer of liquids and gases.

Types of Flexible Metal Hoses

-

Annular Corrugated Hoses:

Corrugations are formed in a ring pattern around the hose, providing excellent flexibility and strength for general industrial use. -

Helical Corrugated Hoses:

Corrugations are continuous in a spiral shape, offering flexibility for dynamic applications with constant motion. -

Single vs. Double Braid:

Single-braided hoses handle moderate pressure, while double-braided versions are used in high-pressure or demanding conditions.

Installation and Maintenance Tips

-

Avoid excessive twisting or bending beyond the manufacturer’s minimum bend radius.

-

Support the hose properly to prevent unnecessary stress on end fittings.

-

Check regularly for signs of wear, braid damage, or corrosion.

-

Always choose the correct hose type and fitting material for your pressure, temperature, and media requirements.

Conclusion

Flexible metal hoses combine durability, safety, and adaptability in a single solution. Their ability to perform under pressure, absorb vibration, and endure extreme conditions makes them indispensable across a wide range of industries. By selecting the right hose type and maintaining it properly, businesses can ensure longer equipment life, reduced downtime, and enhanced operational efficiency.