When you build or maintain products in telecom, electronics, or industrial environments, reliability is everything. One unexpected failure can cause service interruptions, customer dissatisfaction, and costly repairs. That’s why many engineers and reliability teams turn to MTBF Telcordia standards calculators to predict performance and reduce risk.

This guide explains what an MTBF Telcordia standards calculator is, why it matters, and how to use it effectively. We’ll walk through the process in a clear, practical way so you can apply it to real-world projects with confidence.

What Is MTBF in Simple Terms?

MTBF (Mean Time Between Failures) is the average time a product is expected to operate before failing. It is a predictive value, not a guarantee. If a device has an MTBF of 100,000 hours, it doesn’t mean it will run for exactly that long. Instead, it means that across many units, the average failure interval is about 100,000 hours.

MTBF helps teams:

-

Compare component reliability

-

Plan maintenance schedules

-

Estimate lifecycle cost

-

Improve design decisions

Why Telcordia Standards Matter

Telcordia SR-332 is one of the most widely accepted reliability prediction standards, especially in telecommunications and electronics. It provides structured methods to calculate failure rates based on:

-

Part type

-

Operating environment

-

Quality level

-

Stress factors

Unlike generic MTBF methods, Telcordia offers a more realistic, data-driven approach. It considers real-world conditions instead of assuming perfect operation. This leads to more accurate predictions and better product planning.

What Is an MTBF Telcordia Standards Calculator?

It is a tool that applies the formulas and datasets from Telcordia SR-332. Rather than performing the calculations manually, the calculator automates the process. You input component details and environmental conditions, and the tool outputs:

-

Failure rate (λ)

-

MTBF

-

Confidence levels

-

Adjusted values for stress or temperature

Some calculators are spreadsheet-based. Others come as standalone software or online platforms. The best tools also include component libraries and support different Telcordia methods.

Who Uses These Calculators?

Typical users include:

-

Design engineers who want to validate component choices

-

Reliability engineers who prepare reports and predictions

-

Manufacturers who need data for certifications or vendor requirements

-

Quality teams that plan maintenance and field support strategies

-

Product managers presenting reliability metrics to stakeholders

If you build or maintain anything that must stay operational, this tool is worth understanding.

How Telcordia MTBF Calculation Works

Telcordia includes three prediction methods:

-

Method I – Parts Count

Basic approach with generic failure rates. Fast but less accurate. -

Method II – Parts Stress

Includes operating temperature and electrical stress. More accurate, commonly used. -

Method III – Field Data

Combines real failure data with predictions. Most accurate, ideal for mature products.

A good calculator supports at least Method I and II, with some offering Method III for advanced teams.

Key Inputs You’ll Need

Using the calculator requires specific details. The better the data, the more accurate the output.

Typical inputs include:

-

Component type (resistor, IC, connector, capacitor, etc.)

-

Quantity of each part

-

Environment (ground benign, airborne, mobile, uncontrolled)

-

Quality level (commercial, military, automotive)

-

Temperature

-

Electrical stress

-

Service life expectations

Some tools also allow mission profiles or mixed environments.

Interpreting the Output

Once you run the calculation, you’ll see:

1. Failure Rate (λ)

Usually in failures per million hours (FPMH). Lower is better.

2. MTBF

The inverse of failure rate. For example:

-

λ = 10 FPMH → MTBF = 100,000 hours

3. Confidence Levels

Helps understand statistical certainty.

4. Adjustments

Shows how environment or stress impacts reliability.

Understanding these values allows you to compare designs or make improvement decisions.

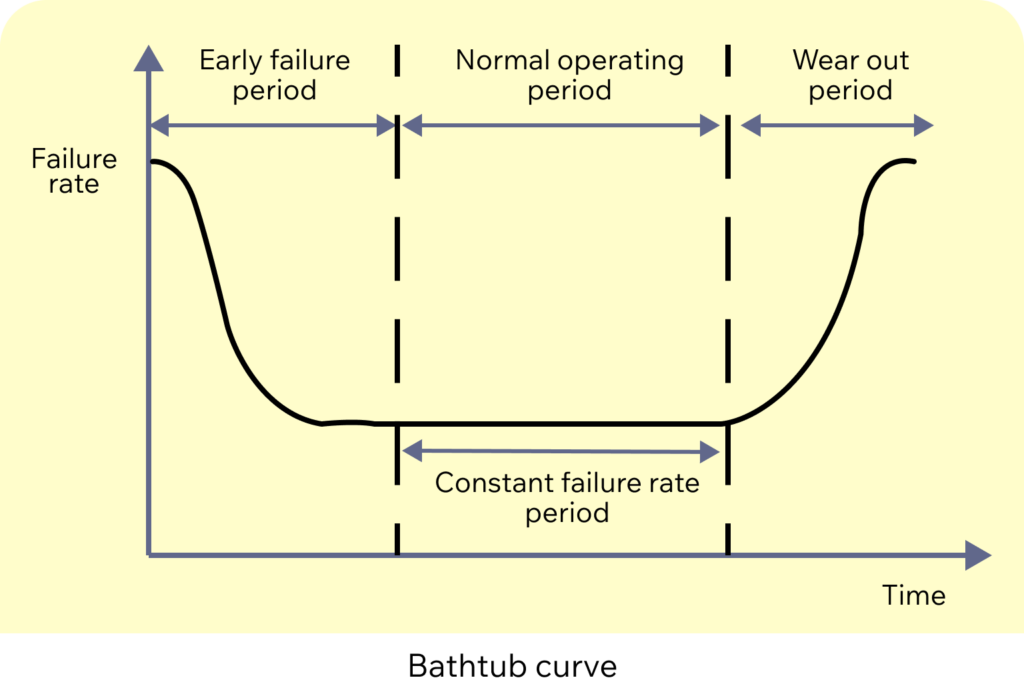

MTBF vs Real-World Reliability

MTBF predicts average failure intervals, but real-life performance includes many variables such as:

-

Aging

-

Manufacturing quality

-

Usage patterns

-

Wear-out mechanisms

That’s why teams use MTBF as a planning tool—not the final word. It works best when paired with testing, field data, and maintenance strategies.

Benefits of Using a Telcordia-Based Calculator

Accurate Predictions

More realistic than traditional parts count models.

Time Savings

Manual Telcordia calculations can be slow. Automation speeds up analysis.

Consistency

Ensures the entire team uses the same method and assumptions.

Professional Reporting

Many calculators export formatted reports for customers or certification bodies.

Improved Design Decisions

Helps you optimize for cost, reliability, and performance.

How to Choose the Right Calculator

Not all tools are equal. Consider the following:

1. Method Support

At minimum, Method II is important.

2. Component Library

Tools with built-in component data save time and reduce errors.

3. Ease of Use

Clear input fields, smart defaults, and clean reports matter.

4. Standards Updates

Look for tools that include the latest Telcordia revision (Issue 3).

5. Integration

Some calculators export to spreadsheets or reliability databases.

6. Reporting Options

Professional summaries or detailed breakdowns help different teams.

Step-by-Step Example of Using a Calculator

Let’s walk through a simplified process:

-

Identify all components in the design.

-

Collect environmental and operating data.

-

Enter part type, quantity, and stress conditions.

-

Choose prediction method (most often Method II).

-

Run the calculation.

-

Review failure rates for each part.

-

Identify high-risk components.

-

Make design adjustments if needed.

-

Generate final MTBF and reliability report.

Repeating this early in product development helps avoid late-stage redesigns.

Common Mistakes to Avoid

Assuming MTBF = Lifetime

MTBF shows average time between failures, not end-of-life.

Using Poor Data

Wrong temperature or stress inputs lead to misleading results.

Ignoring Environment

Indoor vs outdoor conditions can change failure rate drastically.

Treating All Parts the Same

Some components dominate reliability calculations. Others are negligible.

Best Practices for Better Results

-

Use actual operating conditions, not ideal scenarios.

-

Update predictions when design changes.

-

Combine MTBF with lab testing and field data.

-

Track recurring failures to improve accuracy.

-

Share results with design and maintenance teams.

How Telcordia Compares to Other Standards

Telcordia vs MIL-HDBK-217

-

Telcordia is more modern and flexible.

-

MIL-HDBK-217 can be overly conservative or outdated.

Telcordia vs FIDES or IEC-61709

-

FIDES is popular in aerospace and defense.

-

IEC standards are widely used in industrial and automotive sectors.

Where MTBF Data Is Used

Design Reviews

Supports component selection and architecture decisions.

Quality Documentation

Used in reliability plans and compliance reports.

Customer Confidence

Clients often request MTBF data to evaluate product readiness.

Warranty and Cost Planning

Helps optimize replacement schedules and inventory.

Why Accuracy Matters

Even small improvements in prediction accuracy can reduce:

-

Unexpected downtime

-

Warranty claims

-

Maintenance costs

-

Customer complaints

Predictability builds trust—and trust leads to long-term success.

Final Thoughts

An MTBF Telcordia standards calculator is more than a math tool. It is a decision-making resource that helps engineering, manufacturing, quality, and product teams build reliable systems with confidence.

When used correctly, it can reveal potential weak points, guide smarter designs, and support long-term performance goals. Start with accurate inputs, choose the right method, and treat the results as a foundation for continuous improvement.

Reliability isn’t luck. It’s calculated—and the Telcordia standard is one of the most trusted ways to do it.